Product Description

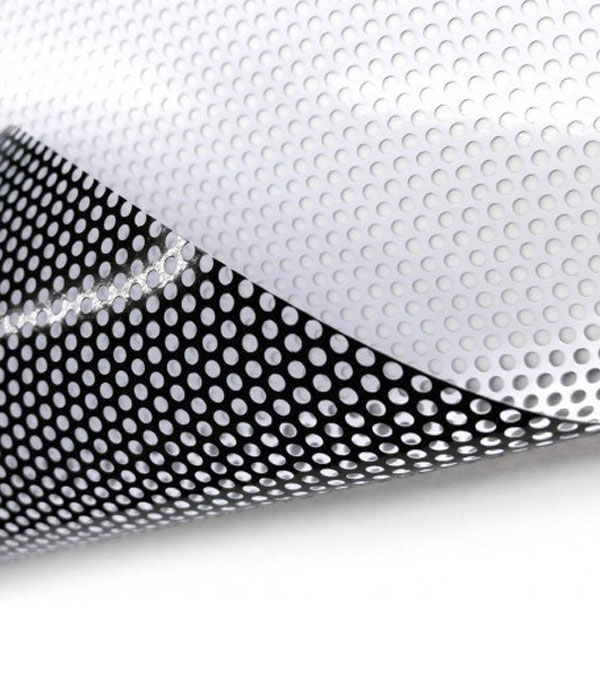

Transform Windows with Custom Adhesive Perforations

- Perforated vinyl allows for see-through window graphics

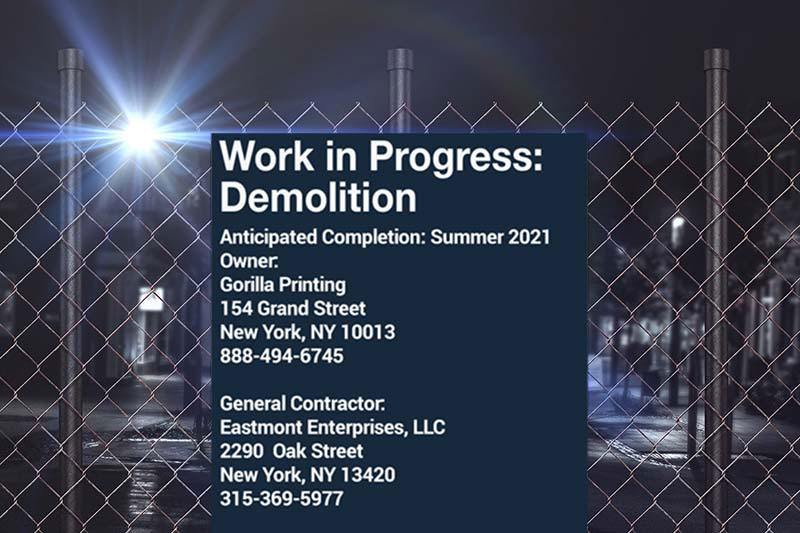

- Customizable with full-color printing for advertising

- Blocks out UV rays to reduce heat and protect interiors

- Removable without damage to glass

Adhesive vinyl is perfect for promoting your brand outdoor. Our environmentally friendly vinyl materials come with a clear permanent adhesive backing, and we can print them in both matte as well as glossy finish. Our adhesive vinyl is printed at 720 dpi resolution to ensure their stunning looks. Available up to a size of 52” high and 159’ wide.

Using these in public? Download Legal & Compliance Regulations

FTC - Advertising and Marketing: Rules of the Road DMV.org - Window Tinting and Window LawsFast Turnarounds

We’re the original same day large format printer. With 3 hour turnarounds on the widest range of products.

Fast Shipping

Get your order fast! We ship Nationwide with trusted UPS couriers.

Expert Support

With over 20 years experience in large format printing, our team can help tackle any job.

Local Printer

We’re your local NYC printing shop. Pickup directly from our store in Brooklyn, NYC.

Case Studies & Campaigns

Why should you print with Gorilla Printing? We’re the trusted printer of over 1500 companies & startups just like yours. With over 20 years experience in large format printing, OOH campaign printing and service, we’ve got the know-how & capabilities to deliver any sized print job.

Jennifer

7-16-21

United States

Verified Buyer

Incredible! Love these.